More Plowden Progress

Graduation

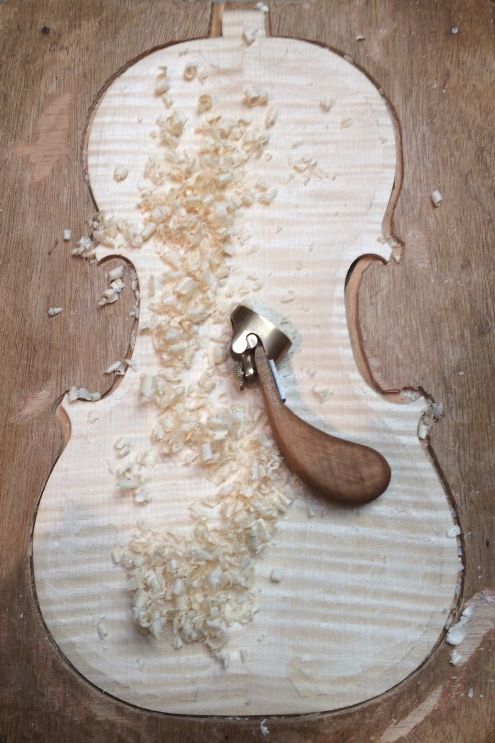

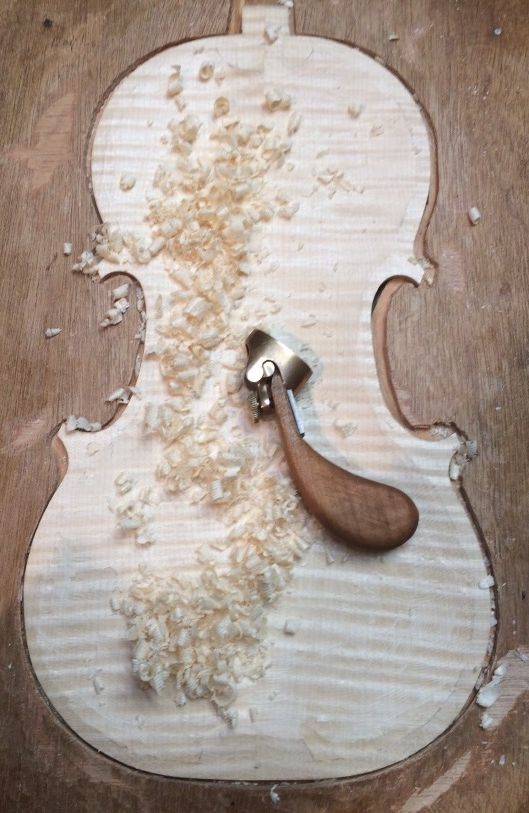

Graduating hard maple can be a tough, laborious job. Besides, there is always the possibility of carving too deeply and ruining the plate. So, I try to cut the risks by creating a “map” by marking the thickness every few centimeters, and then carving the “dots” until each “dot” is about the thickness I want. Finally, I connect the “dots”, using planes and scrapers, checking for thickness as I progress.

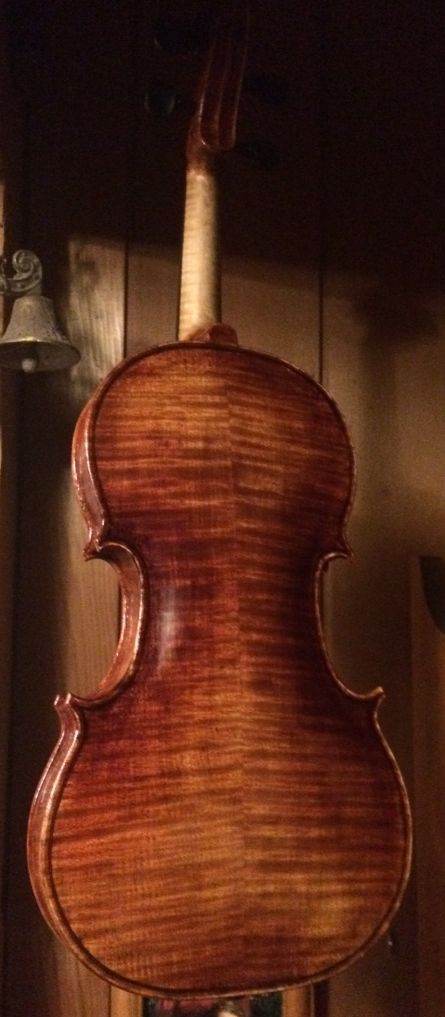

Grafted Scroll and Neck-Set

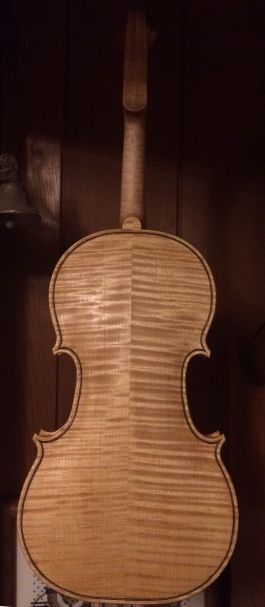

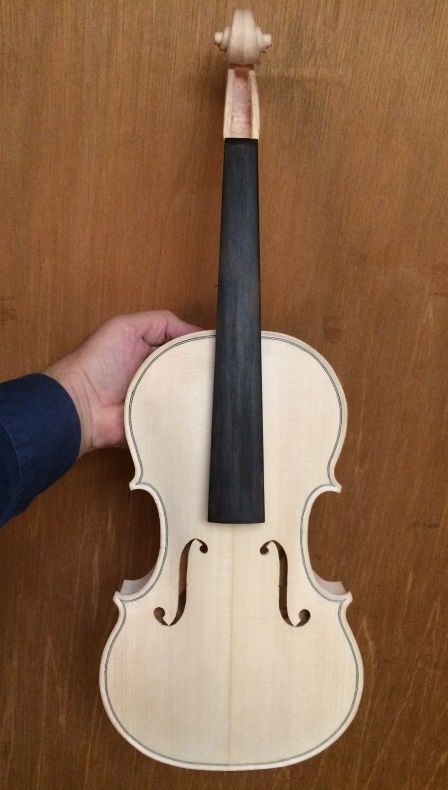

Once the graduations are complete, and the inside of the back plate has been scraped completely smooth, I install the label and I am almost ready to close the corpus. In this case, however, I also had decided to use the scroll I had carved, but graft a new neck to the scroll, as the original neck was too thin: so there was a good deal more work involved. Here is the grafted neck, partially shaped, with the completed back plate:

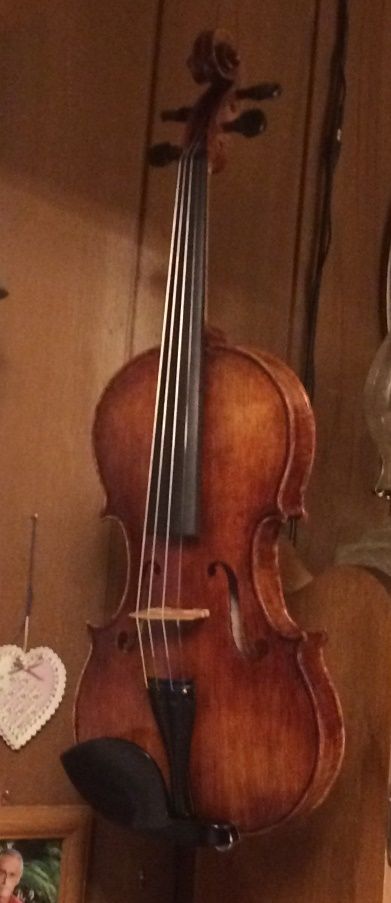

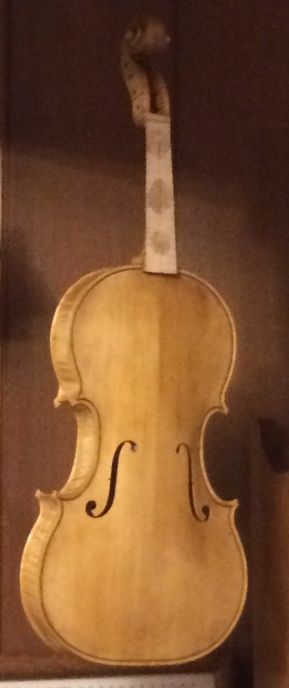

I had been anxious to complete the back plate, and had not yet set the neck. So I completed the neck and installed the fingerboard.

Next I set the neck, so that the angles were all correct.

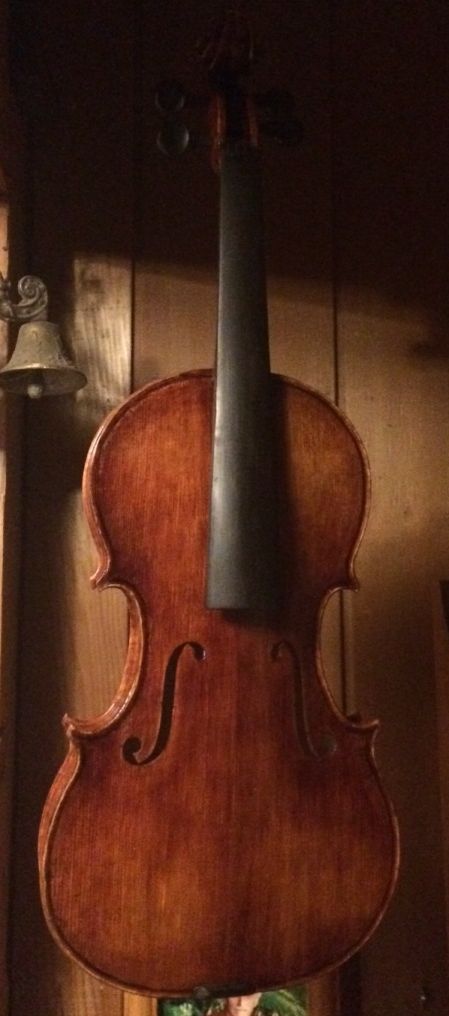

Closing the Corpus

Then I removed the mold, and installed the inside linings on the back edge of the ribs, shaped the linings and the blocks, flattened the back of the garland, and installed the back plate. I use spool clamps and a single large spring-clamp to close the corpus. My wife thinks the spool-clamps look like old-fashioned hair-curlers.

Trimming the Button and Neck Heel

Once the glue was dry, I removed all the clamps, cleaned off any glue that had squeezed out of the joint, and trimmed the button and heel. The dimension from the juncture of the top edge of the front plate and the side of the neck heel (from each side) to the very center of the curve of the heel, should be right at 26 mm. You can see the two marks I laid out with a compass, testing that distance: it was still a little too high in the center of the curve, so the neck needed to be trimmed a little more.

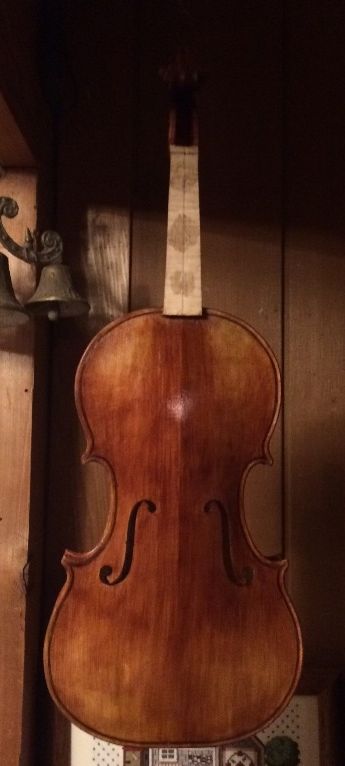

Purfling the Back Plate

Once the neck-heel and button were trimmed, I still had to perfect the outline of the back plate, making certain that the overhang was even all around, as much as possible. Then I laid out the purfling slot, using a purfling marker, and began incising the outlines of the slot.

Next I cut the slot out, using a small knife and a purfling pick, then dry-fit the purfling, after bending it on the bending iron. Finally I glue it in place, using hot hide-glue.

Edge-Work

I marked a crest-line, about 1.6 mm in from the outer edge, then used a gouge and scrapers to carve the channel, and fair it into the plate surface. The edges were all still quite rough,and crude, so I began shaping them, using a small plane, and a half-round file, then sandpaper to get a smooth edge all around. I don’t use sandpaper much, but this is one place where it is appropriate.

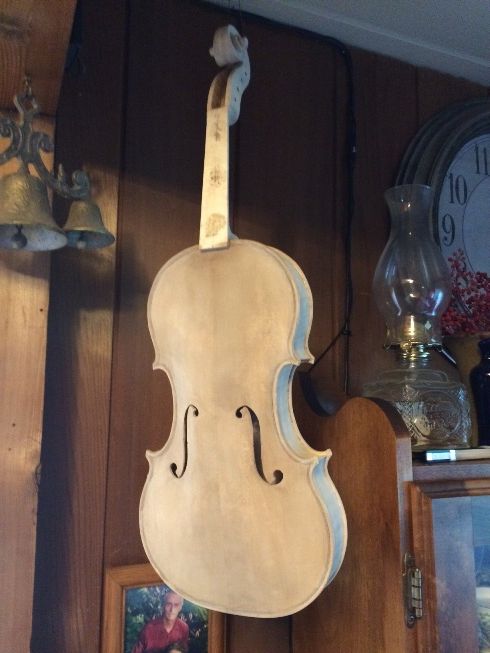

Finishing Process Begun

Once all the varnish preparation is complete, I brush a coat of coffee all over the instrument, to tan the wood a little, and raise the grain. When that is dry, I sand off most of the raised grain, using 400-grit sandpaper. This ensures that the grain will not raise too much during application of the spirit varnish, later. Afterward, I rub in a coat of gypsum in a coffee suspension, to fill the pores of the wood with particles of the mineral. This keeps the varnish from saturating the wood, and possibly dampening the sound.

I expect that, by tomorrow, the sealer will dry sufficiently that I can begin varnishing. I am getting anxious, as the show is a week from tomorrow, and I am far from completing this instrument.

Thanks for looking.

Follow

Follow