What are the wood choices, in Lutherie?

Maple, Spruce, Willow, European, Domestic, Red maple, Big Leaf maple, Sitka spruce, Englemann spruce

Wood Selection: Where does it come from, what kind is it, and does it matter?

Treasure does grow on trees!

Traditionally, violin-family instruments have been made from maple and spruce, pretty much exclusively, though there are relatively rare counterexamples–a viola made of poplar, or willow; a bass made of willow, etc. A large number of scrolls were carved of pear-wood.

Usually, though, the scroll/neck, back plate, and ribs/sides are made of maple, and the belly, or front plate (soundboard) is made of spruce. The bassbar is also spruce, as is the soundpost, which is sometimes called the soul of the instrument. The fingerboard and other fittings are usually made of Ebony, which is an extremely hard, dense, jet-black, exotic hardwood. It is really only available through import. I would like to explore other options, but, for now, Ebony is the best choice. Linings and blocks are typically either spruce or willow, though there is no hard and fast rule on the wood for linings.

So…what do I use?

So far, I have used exclusively maple and spruce for the body of the instrument, but have experimented with a variety of maple species, and three different spruce species. I have a large billet of American Black Cherry from which I hope to make a cello (Back, neck and ribs), someday soon, as a friend, Oded Kishony, has made a very good cello of cherry. (He did warn me, however, that, though its tone was superior, it was difficult to sell; orchestra people are very serious about tradition…)

Paul Schuback and other master makers have taught me that, while domestic maples are fine for larger, deeper-toned instruments, European maple is superior for violins. No one denies that some very nice violins have been made of American maples…they simply recognize that European maple has the edge, as far as violin tone is concerned. I cheerfully bow to their wisdom, and will probably make most violins of European maple or Red maple, from now on. Red maple, from the eastern USA, seems to most closely match European maple.

Here is the Red maple from which I made my #10 instrument (a violin):

Big Leaf Maple

Violas, celli and double basses are another story. Big Leaf maple is somewhat softer, and lighter, but sometimes very beautiful. Evidently its different physical characteristics make it ideal for larger instruments and thicker graduations. Here is a Big Leaf maple log that was given to me, and which is destined to become violas, celli and basses:

Here’s what a piece of it looked like, inside, when I split it:

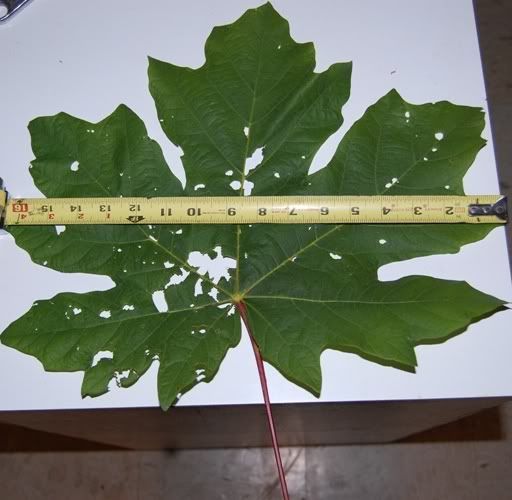

Incidentally; if you have wondered why it is called “Big Leaf” maple, take a look at this:

Willow for blocks and linings

And here is where I get Willow for blocks and linings: I watch for when people lose large limbs in wind or snow storms, and ask if I can remove them. This one was full of a honey-bee nest, but it is good wood.

Here’s what’s left of the nest, still in the tree.

Spruce

So far, I have had to purchase all the spruce I have used. There are some nice stands of Sitka and Englemann spruce here in the Northwest. I hope to go on a “Spruce Safari” someday, and bring home a prize log. 🙂 But I’m getting older, and logging isn’t easy. We’ll see.

In some ways I almost prefer buying the spruce– I can ask for exactly the grain-count I want, and the age (since cutting) I want, and, if I care to drive to the warehouse, I can sort through the stacks and get the exact look I want. But I pay for those privileges, and it is tempting to just find a great log, cut it up myself, and save the money. 🙂 Spruce is nearly always the first choice for soundboards, from violins to pianos, because it has the stiff, lightweight characteristic that resonates best to produce the sound. (A vibrating string by itself makes very little noise…amplified by a spruce soundboard, it can fill a room, or even an auditorium.)

Other Tonewoods

There have been makers who have (quite successfully) used other woods to build instruments. The grip of tradition is strong, however, and makers frequently have a tough time selling instruments that are NOT made of Maple and Spruce. I am willing to try other woods, but if, for example, someone wanted a fiddle out of Zebra-wood, while the idea is intriguing, I can foresee problems, and I would probably want my money up front. The instrument would doubtless be beautiful, and might even play well, but I see it as a risk I am loath to take. The labor is my most costly investment, and it is the same whether I build the instrument of traditional woods, or non-traditional. If I can’t sell it, then I have lost my time and effort, not to mention the cost of the exotic wood. As I mentioned earlier, Oded Kishony made a Cherry cello, and, while the tone actually turned out to be superior, the cello was very difficult to sell. Tradition matters, even today. Pine has sometimes been used for soundboards…even Western Red cedar has occasionally been used. But there is a reason everyone comes back to spruce– it works the best, as a rule. Plenty of counter-examples, I know, but they are in the extreme minority.

There are makers who use Walnut, Western Red Cedar, Pine, Douglas Fir, Pacific Redwood, Cypress, and a host of exotic woods. No problem…but I am at an age where I can no longer afford to take unnecessary risks. I really prefer the traditional woods, anyway. However, I may do some experimentation on the five-string fiddles. Wandering outside the “orchestral sphere” sets one free to experiment a little more.

A friend (Cliff Stansell, of the Pistol River Trio) has recently suggested that I try a fiddle of Port Orford Cedar. It’s nice stuff, and I may give it a go, but it will be a five-string fiddle, whose target market is not nearly so attached to tradition. There are five-string fiddles made of many combinations of exotic or domestic woods. He also asked about a five-string fiddle with an Oregon Myrtle back, sides and neck, and Port Orford Cedar front: it could happen…it surely could. 🙂

(Later Edit: the Myrtle and Port Orford Cedar five-string fiddle turned out very well, and plays superbly.)

Follow

Follow