Completing the Front Plate

Completing the Graduations

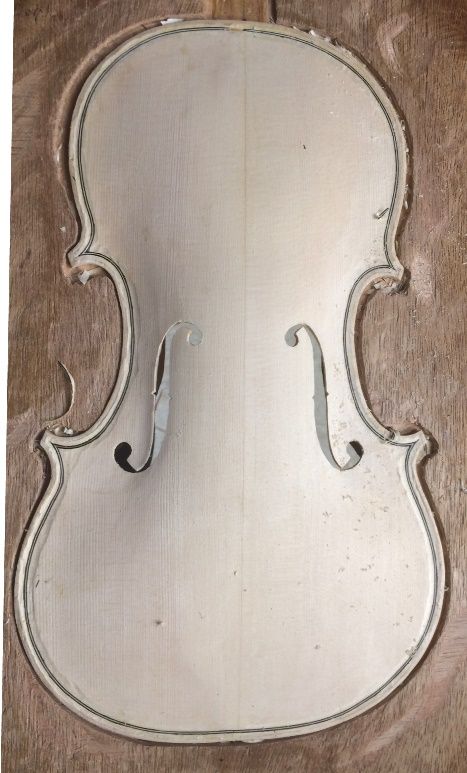

When I last posted, I had just begun the graduations of the front plate. I got tired, and had to stop. It has been frustrating, finding how little I can accomplish, currently, before feeling exhausted. I hope I regain the strength and stamina I once had. Here is what the plate looked like yesterday morning:

The plate was still far too thick, but was at least looking encouraging…so I plunged in and brought the whole plate to approximately 3.5 millimeters thickness all over. This is the first time I have tried this graduation scheme. In the past I have been very particular to have one thickness in the center area, another, slightly thinner, above and below that area, and thinnest of all, out in the flanks. But, I am informed that that is not such a good plan. So…here we go!

Completing the F-Holes:

Once the graduation is complete, I need to finish cutting out the f-holes: I begin with a special tool called an “f-hole drill.” For years I worked without one of these little gems, but my children finally decided I ought to have one, and bought it for me. 🙂 The use of the tool is self-explanatory, and there are a wide variety of bit-diameters, for violins and violas. (I later bought another, larger one, for cello f-holes.)

After drilling the four f-hole “eyes,” I began cutting out the rest of the f-hole outlines, using a knife and a small saw.

Completing the Purfling Channel

Now it is time to start cleaning up the purfling channel, and fairing-in the curves, up into the arching. I began with a sharp pencil, and drew an “edge-crest” line, approximately 40% of the distance in from the plate edge, toward the purfling. Then I used a sharp gouge to remove a shallow channel across the purfling, which ended at the edge-crest. Then I used scrapers to smooth the transition between the edge of that channel and the arching curves.

The treble side channel is essentially complete. When I have the whole channel completed, I will flip the plate over and install the bass-bar. All along the way, I will continue to fine-tune the f-holes, until they are satisfactory. Right now they are quite rough, but my hands are tired, and I am fearful of making errors due to fatigue. So…they can wait. 🙂

Thanks for looking.

Follow

Follow